Warehouse Racking Inspection

YuRacking always has confidence in the racking and shelving we produced. But there is still a need for warehouse racking inspection and maintenance from time to time. In the ordinary loading and uploading processes, such situations as false operation of the forklifts resulting in hitting the frame; forklifts are overloaded (over the loading limitation), safety pin is not fixed well before putting pallets on the beams… All these things are very dangerous, many accidents happened because of this unconsciousness little mistake. So, firstly, we need to deepen our understanding of the importance of safe use of the warehouse racking system and warehouse racking regulations.

Pallet Rack Protection Tips

Here we offer some pallet racking inspection tips here for users to pay special attention, which can do some help to pallet racking maintenance.

Don't Overload

When the racking solution was confirmed, racking materials should be chosen according to your original loading requirement. Because the racking has a loading limitation when it is designed based on your original loading requirement. Never exceed the loading capacity limitation. Overloading may cause the beam connector to roll out from the upright frame. What's worse, overloading may cause the collapse of the whole racking system, which is a very serious accident, people not just lose money, at more serious situation, it may hurt person.

Don't Load Pallets/Goods on the Racks before Confirming All the Safety Pin is Fixed Well

You should confirm that all the bolts and nuts are fixed tightly before you use racking and shelving. And all the protectors are fixed in the right positions, because they will be protective when some accidents happen. The safety pin is very important, it can keep the beam upright when loading and unloading heavy pallets.

Change the Defection Parts Immediately

Even some accessories look like not so important, you should change it to avoid some problem happens, like the rusted nuts and bolts, or the unqualified pallets.

Trained Your Workers Before Using the Racking System

The pallets or cartons need to be put on right places of the racks. If they are not put correctly, it may cause the damage of racking. Especially for the forklift operators, they need to know the importance when dealing with the racking system. Tell them to control the speed, forklifts can't be too fast, and drive carefully, don't hit the other parts of the racking. Remember to put the pallets in the certain position. For example, for the drive-in racking, attention should be paid when the forklift driver goes into the deep bay to load the pallets, cause some false operation may damage the racking.

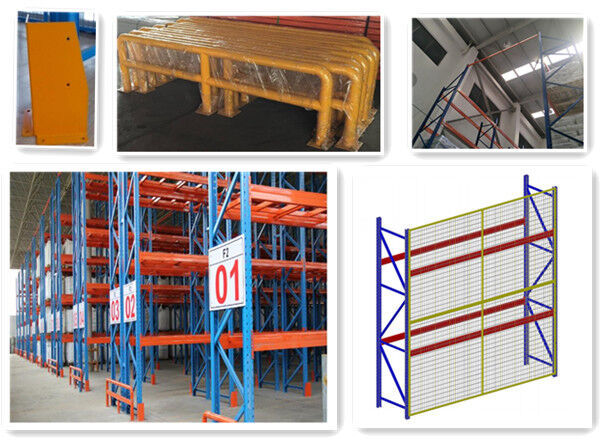

Use the Protection Accessories When Necessary

Like the protection guard for the Upright Frame Barrier for the frame, wire meshing protection for the aisle. below is the picture of pallet racking protection accessories.

Have A Professional Engineer to Maintain Your Warehouse

If your warehouse is large enough, it is recommended to have a certain person in charge of the pallet racking safety inspections, discover the problem and solve it timely.

Check All the Equipment Timely, Widen the Aisle, Be Careful of the Corners, Keep Your Warehouse Clean

All in all, regular warehouse racking inspection can prevent goods and racking system damage, extend the life span of the racking system, and minimize the loss by discovering and solve the problem timely. Effective pallet racking inspection can prevent some serious accidents, protect your goods and workers.

YuRacking can provide these pallet rack inspection services to you or help to train your worker to do this.

Pallet Racking Inspection List

Inspect Frame

· Check Structural Deformation: avoiding any upright frame bend, unsuitable assembly of the upright and bracer, all the nuts and bolts should be fixed well…

· The Footplate is welded or connected firmly to the upright properly;

· The Anchor is connected to the footplate and floor correctly;

· Keep every part in good condition.

Inspect Beam

· Check permanent residual deformation: check if the beam is deformed greater than 20% of the deformation after unloading the beams or nominal deflection (L/250) when loaded;

· Bend of beam;

· Welding: the beam and the connectors welded greatly;

· The safety pin is fixed well;

Inspect the Protect Parts

· Keep all protection parts installed in the proper positions, they can protect the upright, frame, and the whole system greatly;

· Check protector parts timely, if there is any damage or deformation, you need to change and replace them immediately.

Inspect Floor and Aisles of Racking

· The floor must be in good condition: plain and horizontal in the same level. if there is any unlevel in the floor, you should use levelling shims under the upright-footplate to keep the whole warehouse system in the same horizontal level; And the warehouse floor should have good resistance, it can't be sickened easily, because it may make the whole system to collapse when installation;

· Aisles: all the aisles and passageways should be clean, no obstacle.

Inspect Handling Equipment

· Forklift: keep the forklift in good condition before operating. Any disabled forklift should not be allowed to work in the warehouse;

· The forklift operators must be trained and better in rich experience.

Inspect unit loading

· Check the pallets timely, keep them in good condition;

· The goods must be loaded in the pallets correctly;

· The pallet must be loaded on the racking in the correct positions.

Pallet Racking Inspection Requirements

The warehouse racking inspection is especially important for the safety loading. It needs the cooperation of the wholesale shelving supplier and the warehouse owner, only when the two-party work together tightly, then, we can keep the warehouse loading always in a safe condition.

It is suggested that there must be a person in charge of the storage equipment safety, responsible for the whole warehouse racking system, who must inspect all the racking parts and the whole warehouse regularly. If any damage or deformation happens, he finds them timely, and the pallet racking maintenance can be carried out timely.

How Often Should Warehouse Racking Be Inspected

· warehouse personnel can perform these warehouse racking inspections every day: any damage and deformation of the warehouse racking, safety pin missing… these problems are obviously visible and can be founded timely;

· Weekly and monthly pallet racking inspection should be carried out by the warehouse manager;

· Annual pallet racking safety inspections must be carried out by an expert who is experienced in storage equipment safety, who must be responsible for all the inspection report, classify damages and deformation, and arrange corresponding pallet racking maintenance correctly.

Related Racking and Shelving Services

Related Racking and Shelving Products

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective

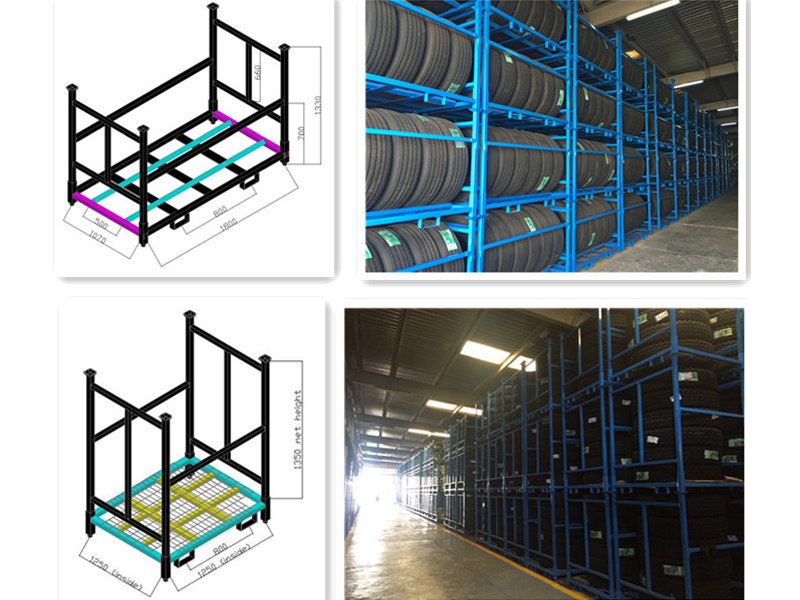

Selective Pallet RackingSelective Pallet Racking is the most economical pallet racking solution, 100% selective Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m

Narrow Aisle Pallet RackingNarrow Aisle Pallet Racking-high density solution, the aisle is just need 1.6m-1.8m Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift

Double Deep Pallet RackingDouble Deep Pallet Racking-four bays together, high density, need the special double deep forklift